When it comes to high-quality joinery, the dovetail joint might immediately come to your mind. Its interlocking pattern looks like a dove's tail feather, hence the name. This unique construction creates a strong and durable joint, making it widely used in woodworking.

In this blog, we will explain its definition, benefits, uses, and types. Whether you seek inspiration for your workpieces or aim to improve your skills, this blog can provide you with an authoritative guide.

What is a Dovetail Joint?

The origins of dovetail joints can be traced back to ancient Egyptian and Chinese imperial tombs, even predating written history. It's used to join two flat workpieces at right angles, and is considered one of the best ways to hold wood together.

Dovetail joints consist of two parts, pins and tails, which create a solid interlocking connection, resisting twisting and pulling forces in certain directions. Crafting a dovetail joint requires precision and accuracy to ensure the joint remains tight.

Mechanical fasteners are not necessary for dovetails. Once they have been glued and clamped, they are nearly impossible to pull apart, withstanding significant pressure and the test of time.

The 90-degree angle makes it suitable for where force is exerted in one direction, making it a preferred choice for creating durable and long-lasting furniture, such as the sides of drawers, furniture, cabinets, sides of solid-wood boxes, etc.

Benefits of a Dovetail Joint

A dovetail joint is widely regarded as a superior joinery technique in the realm of woodworking. We will explore why it is favored over other types of wood joints and remains a staple in woodworking projects.

Exceptional strength

The interlocking tails and pins create a solid bond that can resist pulling forces in multiple directions. Additionally, dovetail joints offer multiple faces for the glue to adhere to. The interlocking design creates numerous contact points along the length of the joint, effectively enhancing the overall strength and durability of the joint. This feature is especially useful in cases where the joint is subjected to load-bearing situations or significant stress.

Resistance to pulling apart

Dovetail joints present excellent resistance to pulling apart due to their interlocking configuration. Dovetail joints remain secure and hold up well under pressure from several sources, such as the weight of stuff kept inside a chest or the frequent opening and closing of drawers. This feature also guarantees the longevity of woodworking projects, reducing the likelihood of joint failure over time.

No requirement for additional fasteners

Because of its interlocking feature, the dovetail joint is more resistant to failure and reduces the need for additional fasteners like nails, screws, brackets, dowels, or any other types of fasteners. Handcrafted nails and screws are comparatively costly, prone to rust and expansion, and occasionally cause the wood they fasten to crack. Therefore, it also eliminates the risk of fasteners loosening or breaking down over time, ensuring the joint's long-term stability.

Aesthetic appeal

There is no doubt that dovetail joints create a visually appealing pattern that adds a touch of craftsmanship and elegance to the piece of work. The precise fit and clean lines of the joint contribute to the overall quality and attractiveness of the finished piece.

Durability and longevity

The interlocking design of the pins and tails has great strength and forms a strong bond over long periods of time. Archaeological evidence even suggests that dovetail joinery has been used for thousands of years, further confirming its exceptional durability and longevity. Additionally, compared to simpler joints like dowel joints or butt joints, the dovetail joint is less prone to loosening or cracking over time. This inherent durability and longevity make it a preferred choice for furniture pieces intended for long-term use.

Types of Dovetail Joints

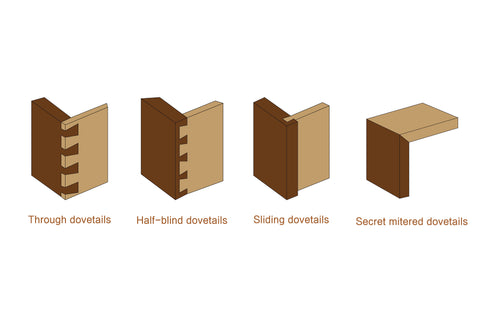

Dovetail joints are the hallmark of high-quality construction, and you can find them anywhere, such as tables, desks, and boxes, especially in cabinetry and drawer construction. Dovetail joints come in a variety of types, and an expert craftsman will know which type is appropriate for a given work. Sliding dovetails, half-blind dovetails, through dovetails, and variations are utilized in the construction of drawers, cabinets, and even some musical instruments. These specialty dovetails are also quite helpful for joining wood at different angles and covering up obvious joints.

Through dovetails (also known as English dovetails)

Through dovetail is the most basic and common type of dovetail joint. In this joint, the tails and pins are visible from all sides. This joint is often used in drawer construction, box making, carcass framework, and other applications where both strength and aesthetics are important. It provides strength and durability, making it suitable for heavy-duty applications.

Half-blind dovetails (Single-lap dovetail)

In a half-blind dovetail joint, the end grain of one board is concealed within a groove or dado on the surface of the other board but is only visible from one side of the joint. This type of joint is commonly used in drawer construction, where the end grain of the drawer front is hidden from view and differs from the through dovetails that are visible from both sides of the boards, creating a cleaner and more visually appealing appearance without the need for adding other decorative elements. Half-blind dovetails are often favored in fine furniture making for their combination of strength and seamless look.

Sliding dovetails (also known as French dovetails)

Sliding dovetail joints consist of a dovetail-shaped groove or dado cut into one board and a corresponding dovetail-shaped tongue or tenon on the connecting piece. Precise cuts and craftsmanship are vital during woodworking. When two wood pieces are assembled at right angles, the tongue slides into the groove, creating a strong and secure connection. Sliding dovetail joints are commonly used in joinery where movement or expansion and contraction of the wood is anticipated, such as in table aprons, cabinet sides, table frames, shelf supports, or musical instrument construction, like guitars and violins.

Secret mitered dovetails

Secret mitered dovetails, or full-blind dovetail joints, combine the strength of dovetail joints with the clean, seamless appearance of miter joints. This joint creates a completely clean look and seamless finish that is completely invisible from both the inside and outside corners.

In this type of joint, the ends of the boards are mitered at a 45-degree angle, creating a continuous grain pattern across the joint. The dovetails are then cut into the mitered edges, providing additional strength and stability.

Secret mitered dovetails are commonly used in high-end furniture and cabinet making for their exceptional strength and durability, such as in box work, high-quality cabinet construction.

Each type offers its unique characteristics and applications, allowing woodworkers to choose the most suitable joint for their specific project requirements.

Whether you're building furniture or engaging in woodworking projects, dovetail joints provide a robust and enduring solution. Suppose you need to create a durable, secure, and long-lasting joint. Feel free to contact us for the quickest, most efficient, and precise solution.

Findbuytool provides a full selection of industrial-grade dovetail router bits, and other joinery router bits like tongue and groove router bits, and lock miter router bits to create a flawless finish and to best connect your woodworking project.

FAQ about Dovetail Joint

Absolutely. It can help the joint achieve maximum strength and durability.