Planers and jointers are two common woodworking tools that can help you handle rough lumber. But both of them are expensive for beginners, so it's important for all of you to know the differences between them.

Before you decide to buy, read this blog carefully. We will explain to you what a planer and a jointer are used for, and how to use them to handle the rough lumber. But there is one thing you need to know, only a jointer or a planer is not enough. Now, here we go!

What is a Jointer?

A jointer, also called a surface planer or a planer in the UK, consists of an infeed table, an outfeed table, a cutterhead, and a fence. It's used for creating flat, smooth, and straight surfaces and edges.

The main feature of the jointer is removing any cupping, bowing, or warping, resulting in a flat reference surface of the board. However, a jointer is not designed to reduce the overall thickness of a board. And it can't ensure both faces of a board are parallel.

On the other side, a jointer can't create an S4S board like a planer due to its reliance on the flat table as a reference surface. When processing, only the surface that contacts the table will be cut, which leads to uneven removal of material and makes a board that is not uniformly flat or of consistent thickness.

For making an S4S board, experienced woodworkers commonly use a combination of tools, such as a jointer and a planer, sometimes a jointer-planer combo, or a table is also needed to achieve the expected results.

What is a Planer?

A planer, also called a thickness planer, consists of an outfeed table, an infeed table, and a cutterhead, just like a jointer. It's used to reduce the thickness of lumber and create uniform thickness, taking the surface below as a reference.

During processing, pushing the board passes through the planer, and the cutterhead will remove a thin layer from the surface. And the bed can be vertically adjusted to control the removed thickness. For a consistent thickness, repeat this step until the mixture is uniformly thick.

Compared to a hand planer, a thickness planer can save more effort and time to plane multiple rough lumber pieces, resulting in smoother and parallel boards.

However, a planer also has some limitations. As we mentioned before, it needs to take the below surface as a reference to maintain a smooth board with a consistent thickness; thus, before you use a planer, a jointer or hand planers are required for the initial flattening.

We tested the 6 best benchtop thickness planers and explored them in detail, including performance, key features, prices, and considerations. Maybe you can take it as a purchasing reference.

What are the Differences: Planer and Jointer

Both the jointer and the planer are essential tools in woodworking, each serving distinct purposes and specific functions. Here are the primary distinctions between a planer and a jointer.

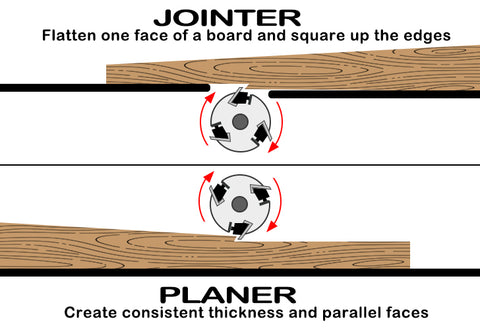

Cutterhead position

- Jointer: The cutterhead of a jointer is mounted underneath the wood board. As they rotate upwards, the blades or knives make contact with the bottom surface of the board.

- Planer: The cutterhead of a planer is mounted above the board. As they rotate downwards, the knives or blades make contact with the top surface of the board.

Functions and capabilities

- Jointer: A jointer can flatten a surface and straighten an edge, suitable for removing initial imperfections, like bows, twists, or cups. But it can't make two surfaces to edges parallel to each other.

- Planer: A planer is more suitable for making consistent thickness and parallel faces on already flattened and straightened lumber.

Size and shape limitations

- Jointer: For the sizes of jointer, 6" and 8" are predominant. Jointers are typically limited by the width of their bed. Boards wider than the bed cannot be flattened using a jointer, so larger boards may require alternative methods.

- Planer: Planers are usually 12" to 13", with larger machines available. Planers can handle wider boards compared to jointers. However, the thickness capacity and the amount of material that can be removed in a single pass are limited.

Usage sequence

- Jointer: In woodworking projects, the jointer is generally used first to create a flat reference surface and square up one edge of the board.

- Planer: Following the jointer, the planer is then used to bring the board to its final thickness and smoothness, ensuring that both faces of the wood are parallel with a consistent thickness.

Why You Might Need a Jointer-Planer Combo?

Both planers and jointers have distinct purposes in woodworking and play an important role in handling rough lumber. But here comes a question: whether to buy a jointer or a planer first? Actually, it depends on your specific woodworking requirements, budget, projects, and long-term goals.

If you need to handle rough and uneven lumber or need a flat reference surface and square edges, a jointer might be suitable; while if you focus on making a board uniform in thickness with two parallel surfaces or working with pre-surfaced boards, a planer might be your best choice.

However, if you need all the functions, a jointer-planer combo is an ideal choice. The jointer is mounted on top of the machine, with the planer underneath. which can save space and money, making it a practical choice for many woodworkers.

Final Thoughts

In conclusion, a jointer and a planer serve different purposes but have an important place in woodworking. Consider your project requirements, budget, and the sequential use of a jointer and planer to make an informed decision.

Findbuytool wood planers offer you board thickness with precise measurements. We sell 3 cost-effective thickness planers: FB131H, FB131, and FB132H.

Among the three, FindBuyTool FB132H is a new one, which has 2 adjustable speeds: 26 FPM and 14 FPM. In addition, it equips a pre-installed 2-row helical cutterhead with 30 carbide inserts, eliminating the need to install it yourself.

By the way, we've published a review about the 2-speed thickness planer, explaining why it's better than the planer with fixed speed. Hope it's helpful for you!

If you still have any questions about the jointer, the planer, or our products, please leave a comment with an available email address, and we will reply to you ASAP!

FAQ about Planer and Jointer

#1 Do you really need a jointer and planer?

Well, they have distinct features. So before you buy it, you need to know the differences between them and choose the most compatible one according to your requirements and projects.

#2 Can a planer be used as a jointer?

Definitely not. A planer is used to create consistent thickness and parallel faces on already flattened and straightened lumber, while a jointer is used to flatten a surface and straighten an edge, suitable for removing initial imperfections, like bows, twists, or cups.