A mortise and tenon is a fundamental woodworking joint used to join two pieces of wood at a right angle to each other. It provides excellent strength, durability, and structural integrity.

The joint has been securing wooden structures for thousands of years. Crafting a precise and accurately fitting mortise and tenon joint by hand, as was done centuries ago, requires a level of skill and proficiency beyond what is typically possessed by woodworking novices.

Nowadays, tools like routers equipped with bits offer more accessible alternatives. However, even today, attempting to create these joints by hand remains a daunting task, especially for individuals who are considered novices.

The precise layout of the joint is just as critical as the subsequent cutting and shaping processes. Even if the tenon is impeccably shaped, any discrepancy in its size or form could result in disastrous consequences.

In this article, we’ll take you through the basics of the mortise and tenon joint, including its definitions, features, a few variations of this fundamental joint, and how to make this joint correctly.

What is a Mortise and Tenon Joint?

The mortise and tenon joint, recognized as the oldest and most robust joint in woodworking, consists of two distinct components: the mortise hole and the tenon tongue. This joint is typically employed to join two pieces of wood at a 90-degree angle.

Presently, it remains one of the most prevalent joints used in woodworking, finding application in the construction of diverse items such as cabinets, chairs, tables, frames, paneling, windows, and doors.

Nonetheless, in any form of construction, mortise and tenon joints require incredibly precise craftsmanship to ensure they work properly.

The mortise is a recess or hole where the tenon goes and is cut into one piece of wood, known as the stile. It’s typically a square or rectangular shape, although it can also be round or other shapes depending on the design. The mortise is created by removing material from the wood using tools such as routers, chisels, or drilling machines. It is usually located near the end or edge of the wood, where the joint will be formed.

The tenon is a tongue or projection that is formed on the end of a corresponding member, generally referred to as a rail. It is shaped to fit precisely into the mortise, creating a secure and tight connection. It is created by removing material from the end of the wood to leave a projecting portion that fits into the mortise.

Advantages & Disadvantages of a Mortise and Tenon Joint

This basic joint consists of a slot (the mortise) cut into one piece, which accepts a tenon cut at the end of another piece. Glue is employed to ensure complete security, or variations of pins, glue, and wedges are utilized to enhance locking further.

This joint offers several advantages: exceptional strength and longevity, versatility, and aesthetic appeal. Renowned for their exceptional strength, whether relying solely on their interlocking design or reinforced with glue or pins, this joint is difficult to separate and simultaneously contributes to the structural integrity of the assembly.

Additionally, this joint can be used in many types of projects, such as various furniture pieces, cabinets, doors, and more. However, many woodworking beginners find them daunting initially, they usually require more precision, time, and skill.

Pay attention, while suitable for a variety of material sizes, this joint may not be suitable for thin material sizes.

Types of Mortise and Tenon Joints

There are multiple variations of mortise and tenon joints, including haunched tenons, loose tenons, pegged tenons, mitered tenons, through tenons, and wedged tenons. Depending on your needs, choose the joint that works best for your project. We’ll demonstrate a few variations for you, some of which don’t even need glue.

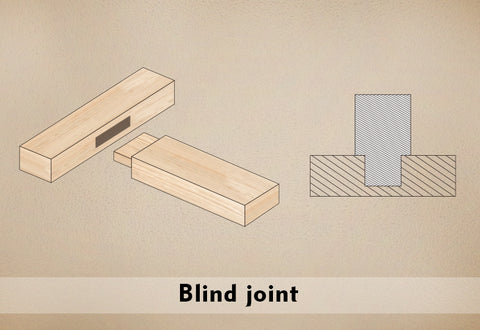

Blind joint

The blind mortise and tenon joint, also known as a “hidden” or “stub” joint, is a type of joint where the mortise does not pass completely through the mortised material, and therefore, when the joint has been constructed, the tenon is invisible. Instead, it creates a cavity or pocket for the tenon to fit into, thus effectively concealing the end grain of the tenon.

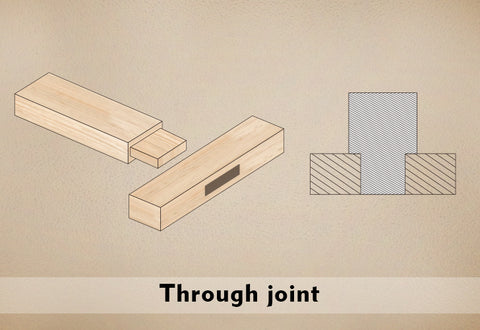

Through joint

The through mortise and tenon joint, also known as an “open” joint, is characterized by the mortise passing entirely through the stile and then sizing the tenon so that it fits flush with the stile’s far side.

This design allows the tenon to terminate flush with the outer face of the mortised material or to extend beyond the surface. It’s an extensively employed joint by cutting the mortise through the stile and then sizing the tenon to align flush with the stile’s far side.

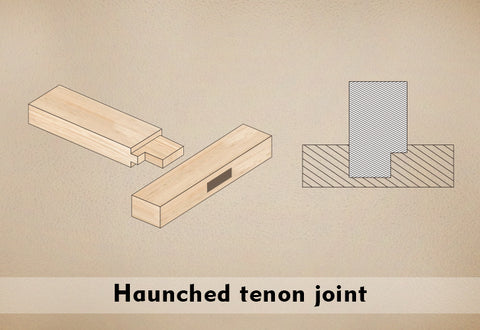

Haunched tenon joint

The haunched tenon joint is commonly used in heavy-duty frame and panel assemblies. In this joint, a short tongue, called a haunch, protrudes from the shoulder of the rail, filling the groove between the rail’s edge and the tongue’s edge.

This joint offers several benefits, such as providing additional strength, preventing the joint from twisting, minimizing voids, and maintaining alignment.

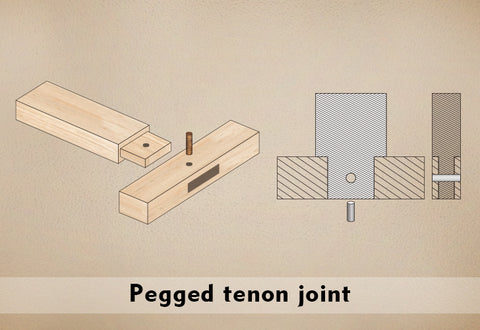

Pegged tenon joint

The pegged tenon is a type of mortise and tenon joint that incorporates the use of small-diameter pegs driven through the joint, perpendicular to its face, to provide additional reinforcement. While modern adhesives offer significant strength, pegs are more frequently employed for decorative purposes rather than as essential reinforcement.

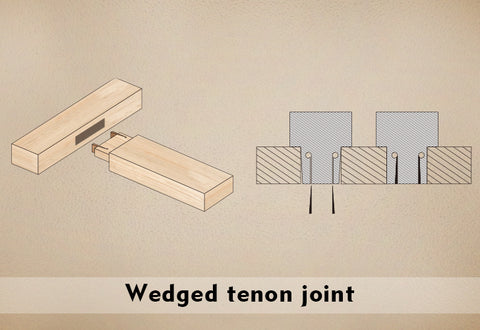

Wedged tenon joint

The wedged tenon joint utilizes wedges to enhance its strength. The end of the tenon that extends through the mortise is widened; this widening creates a dovetail shape on the tenon, which corresponds to a similarly shaped cut in the outer face of the mortise.

It is possible to add a wedge to reinforce the joint even further. The end of the tenon has a thin kerf slot cut into it. To secure the joint, a wedge is driven into the slot after the tenon is inserted into the mortise.

Such wedged joints may not even require glue, particularly if the mortise is tapered to be wider at the wedge end. This design prevents the joint from being pulled apart by sheer force.

Cutting a Mortise and Tenon Joint

Various tools can be employed for creating mortise and tenon joints, chisels, drills, plunge routers, hand saws, and table saws are some of the common tools used in the process, and each offers different levels of precision and ease of use.

Typically, mortise and tenon joints start with cutting the mortise, where the size is determined by the wood board’s width and thickness. A plunge router with an up-cut spiral router bit is the preferred power tool for cutting a clean mortise bottom.

Secondly, the tenon is cut to fit into a mortise using a table saw equipped with dado blades to create accurate and precise tenons, with the height adjusted for shoulder and face cut, and the fence to ensure the correct length of the tenon.

Finally, glue is generally used to fasten the joints together. But before applying glue, fit the mortise and tenon together to ensure they align properly. Disassemble the joint, apply glue, and then reassemble it using clamps and inserting the pins. Once the glue has dried, trim any protruding pins or dowels and remove the clamps.

Choosing the Right Mortise and Tenon Joint Bit

When cutting mortises and tenons, it's crucial to choose the right tools and employ proper techniques for efficient and accurate results.

Spiral up-cut carbide bits, which feature helical flutes, are recommended for plunge routing mortises due to their ability to prevent bit jamming and overheating, providing superior chip clearance compared to straight bits.

While solid carbide spiral bits command a higher price, they offer longer edge retention and are preferred for their durability and performance compared to the high-speed steel (HSS) version.

By understanding the steps and utilizing suitable tools, woodworkers can achieve strong and precise mortise-and-tenon joints in their projects.

Findbuytool offers solid carbide up-cut spiral router bits that are ideal for various routing applications like cutting, flush trimming, grooving, panel sizing, etc. Available in various sizes to cater to your specific needs.

Compatible with CNC machines, handheld routers, and router tables for versatile use. We also offer a full range of top-quality straight router bits, down-cut spiral router bits, and compression router bits for your woodworking needs.