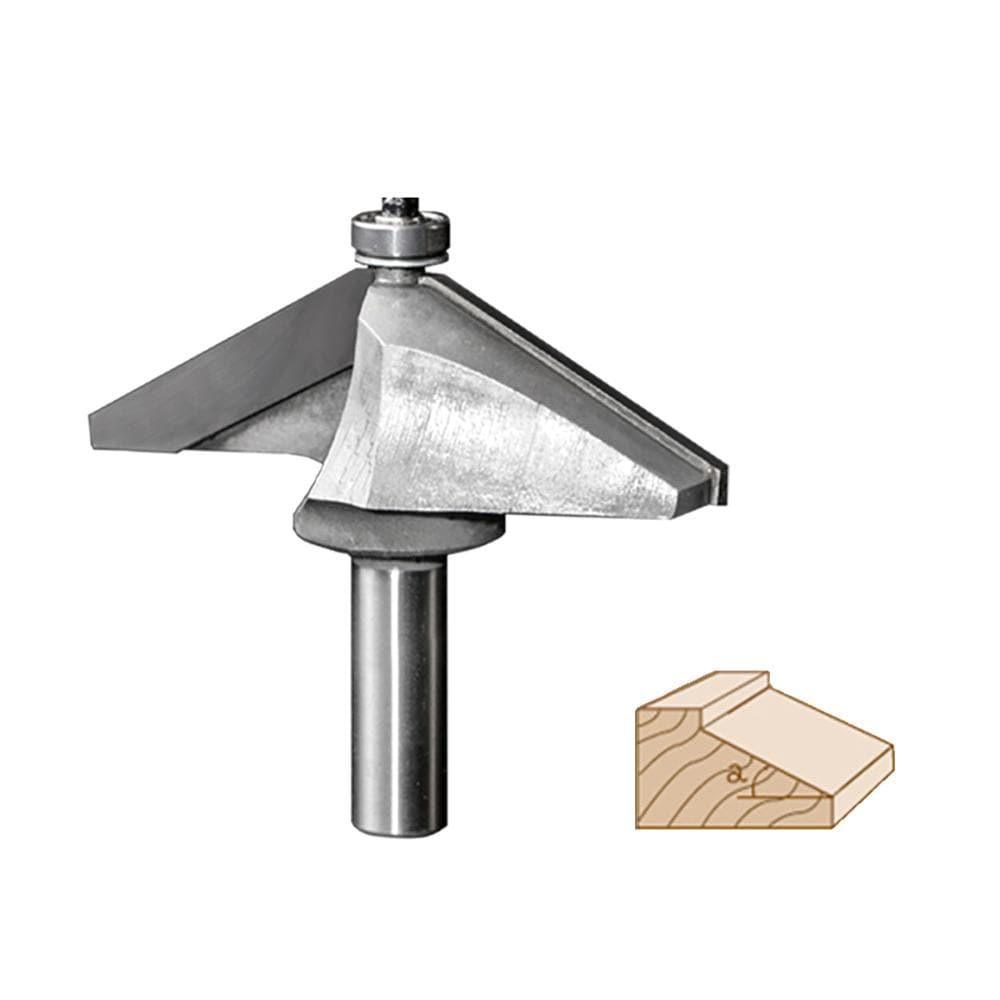

Bit Router de la nariz de los caballos de 25 y 30 grados

FREE Shipping & No Tax at checkout

Bit Router de la nariz de los caballos de 25 y 30 grados - 1 / 4 x 1 / 4 está agotado y se enviará tan pronto como vuelva a estar disponible.

No se ha podido cargar la disponibilidad de recogida

Fast and Free Shipping

Fast and Free Shipping

We will ship item within 1–2 days and deliver to your door in 3–10 days. For orders from other countries, we use international logistics, and delivery is successful in 3-15 days.Enjoy hassle-free shopping today!

30-Day Money-Back Guarantee

30-Day Money-Back Guarantee

You can return a Findbuytool product which states that it comes with a 30 day money back guarantee within 30 days for a full refund for any manufacturer defects or product quality issues.

12 Months Limited Warranty

12 Months Limited Warranty

We offer a 12 MONTHS warranty for quality-related issues and lifetime technical guidance from the date of purchase for FindBuyTool router bits. Learn More.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Trusted Delivery

- Purchase

- Description

- Spec

- Reviews

Sharp Cuts with Carbide Blades

Findbuytool router bits are equipped with high-quality carbide blades that stay sharp for an extended period, unlike cheap router bits that dull quickly or even break after just a few uses. Whether you're cutting softwood, hardwood, or resin-coated wood, our high-quality router bits are always durable and reliable. Their long-lasting sharpness ensures clean, precise cuts with significantly less burr, tearing, and fuzz.

20x Longer Service Life

Our router bits are made from wear-resistant carbide and high-quality carbon steel, welded using a high-frequency seamless process to ensure strong, durable welds that are not prone to breaking. Suitable for a variety of woods, including hardwood and plywood, these router bits offer exceptional durability and a service life that’s 20 times longer than cheaper alternatives. This reduces the need for frequent replacements and lowers long-term tool costs.

High-Precision Cutting with Reduced Vibration

Thanks to precision machining, our router bits provide accurate dimensions and high-speed cutting while minimizing vibration. This not only ensures smooth, precise cuts but also reduces the need for post-cut sanding. Every cut is sharp, clean, and accurate, improving both your efficiency and the quality of your results.

Features of FindBuyTool Router Bits

-

![High-Precision Cutting with Reduced Vibration]()

High-Precision Cutting with Reduced Vibration

Thanks to precision machining, our router bits provide accurate dimensions and high-speed cutting while minimizing vibration. This not only ensures smooth, precise cuts but also reduces the need for post-cut sanding. Every cut is sharp, clean, and accurate, improving both your efficiency and the quality of your results.

-

![High-Temperature Resistance up to 1000°C]()

High-Temperature Resistance up to 1000°C

Our router bits offer excellent thermal stability and can withstand temperatures up to 1000°C. This ensures optimal heat dissipation during high-speed cutting, preventing overheating and wood burning. With these cutters, you can confidently tackle long, continuous cutting tasks without compromising performance.

-

![Suitable for Various Routers]()

Suitable for Various Routers

Our CNC router bits are designed with broad compatibility in mind. With 1/4-inch and 1/2-inch shanks, they are convenient for use with most common router models. They are perfect for home woodworking enthusiasts and compatible with a wide range of woodworking tools.

La broca de borde de bisel de ángulo bajo sin rodamiento está diseñado para acompañar o ablandar bordes. Cortará un ángulo de 25 °/30 ° (o 65 °/60 °) en su pieza de trabajo, como el borde de la mesa. También se puede usar para crear juntas de inglete para una caja. También ofrecemos los bits de enrutador bisel de borde de otros ángulos, incluidos 10 °, 12 °, 15 ° y 24 °.

Características

Características

- Findbuytool suministra una línea completa de grado industrial bits de enrutador.

- Grado industrial, con tecnología de soldadura avanzada, puede confiar en nuestra calidad.

- Para nuestra precisión estándar europea, Ceratizit suministra puntas de carburo premium.

- El rodamiento de la guía puede guiar el bit mejor junto con la pieza de trabajo.

- La nitidez duradera garantiza un corte continuo.

Para una mejor seguridad, sugerimos usar nuestros brocas de enrutador de nariz de caballos de chaflán en una mesa de enrutador o una máquina de enrutamiento, en lugar de un enrutador de mano.

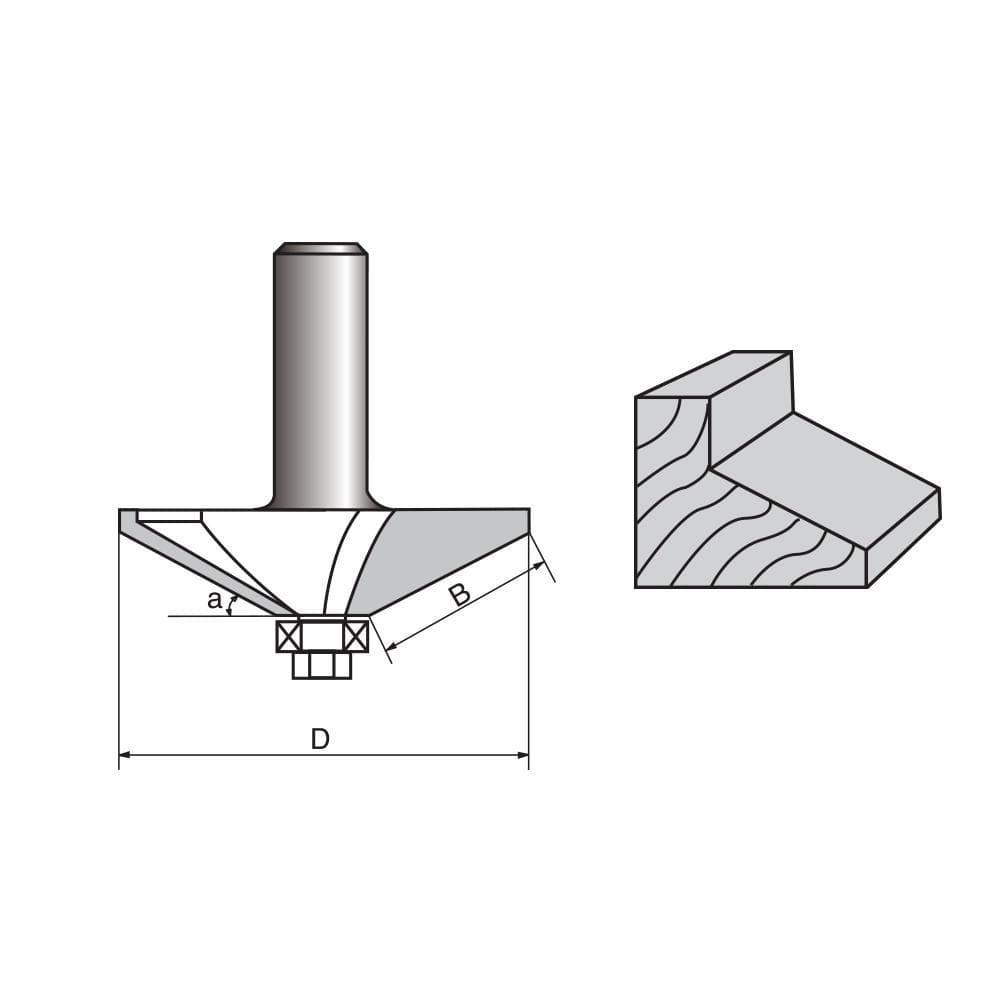

Información técnica

Información técnica

| Tamaño de vástago X B(En.) | D (mm) | α | B (mm) | Material |

|---|---|---|---|---|

| 1/4 x1/4 | 24.49 | 25° | 6.35 | Carburo de tungsteno |

| 1/4 x5/16 | 27.37 | 25° | 7.92 | Carburo de tungsteno |

| 1/4 x 3/8 | 30.2 | 25° | 9.52 | Carburo de tungsteno |

| 1/4 x 1/2 | 36 | 25° | 12.7 | Carburo de tungsteno |

| 1/2x1/4 | 24.49 | 25° | 6.35 | Carburo de tungsteno |

| 1/2 x 5/16 | 27.37 | 25° | 7.92 | Carburo de tungsteno |

| 1/2x 3/8 | 30.2 | 25° | 9.52 | Carburo de tungsteno |

| 1/2 x1/2 | 36 | 25° | 12.7 | Carburo de tungsteno |

| 1/2 x5/8 | 41.82 | 25° | 15.9 | Carburo de tungsteno |

| 1/2 x 3/4 | 47.8 | 25° | 19.1 | Carburo de tungsteno |

| 1/2 x 7/8 | 53 | 25° | 22.2 | Carburo de tungsteno |

| 1/2 x1 | 57.4 | 29° | 25.4 | Carburo de tungsteno |

| 1/2x1-1/8 | 62.5 | 30° | 28.6 | Carburo de tungsteno |

| 1/2 x1-1/4 | 68 | 30° | 31.8 | Carburo de tungsteno |

| 1/2x1-3/8 | 73.49 | 30° | 34.9 | Carburo de tungsteno |

| 1/2x1-1/2 | 78.98 | 30° | 38.1 | Carburo de tungsteno |

| 1/2x1-5/8 | 84.5 | 30° | 41.3 | Carburo de tungsteno |

| 1/2 x1-3/4 | 90 | 30° | 44.45 | Carburo de tungsteno |

Aplicaciones

Aplicaciones

- Madera

Máquina

Máquina

- Enrutador CNC

- Enrutador base fijo

- Enrutador

- Mesa del enrutador superior del banco

Diámetro de envío

Diámetro de envío

- UNIDAD

- Pcs

- Peso neto

- 50

- Paquete

- En caja de plástico

- Tamaño del paquete

- 95 x 18 x 18 mm

Router Bits FAQs

Is it compatible with Bosch/Makita/Dewalt/Festool routers?

Is it compatible with Bosch/Makita/Dewalt/Festool routers?

This bit is compatible with all common handheld routers with 1/2inch shank or 1/4inch shank collet, corded and cordless.

What kind of wood can be milled with these bits?

What kind of wood can be milled with these bits?

Suitable for soft wood, hard wood and various other wood-based materials (plywood, MDF, chipboard, etc.).

What material is router bit made of?

What material is router bit made of?

The blade features carbide tips, and the handle is made of high-quality carbon steel

What's your return policy?

What's your return policy?

Due to quality or product defects, we offer a 30-day free return policy. For more specific return and refund, pls check our return policy.