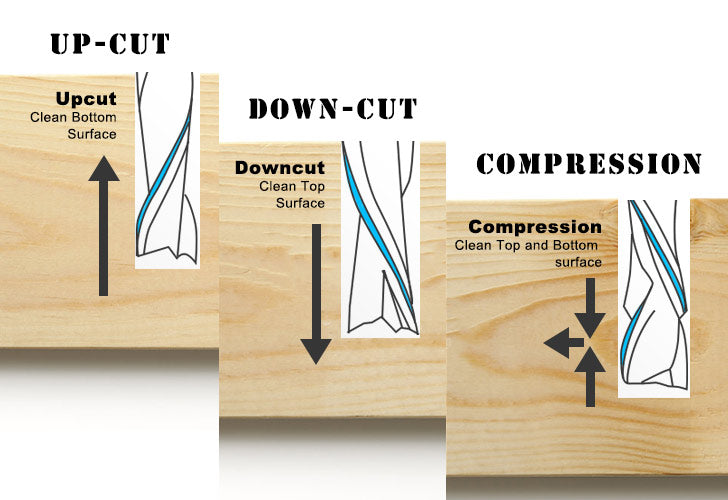

Upcut, downcut, and compression are three types of spiral router bits with different flute directions in the CNC router industry. Due to the angled cutting edges, they are commonly used for plunge routing, and can reduce heat buildup, improve chip evacuation, and make a clean cut.

For beginners, here come questions about which one to choose, or how to choose the best upcut, downcut, or compression in the woodworking process. In this blog, we will introduce them to you one by one in detail. After reading, you can choose the most compatible bit to get the best cutting effect.

What is an Upcut Router Bit?

Upcut spiral router bits, as the name suggests, eject chips upward from the slot. This cutting method can reduce the chips from the bottom to ensure a smooth bottom, but gain a rough top surface.

Due to their features, upcut bits are ideal tools for straight plunging. They are also the best choice for making a dado or groove in straight-grain hardwood, such as walnut and maple, to enhance cutting efficiency.

The upcut spiral router bits will pull projects away from the workbench when working on a router table; thus, please ensure you have suitable clamps when working with small workpieces.

What is a Downcut Router Bit?

Downcut spiral router bits are opposed to the upcut. They can minimize the chips on the top to ensure a smooth upper surface, but produce some tear-out at the bottom. This cutting method is suitable for materials that are easy to tear out or splinter, such as plywood or veneers.

Given that the chips will be pushed into the cut and buildup, it will produce more heat, causing burning and reducing the lifespan of the bit. Therefore, it's important for you to feed slowly to ensure safety while processing.

What is a Compression Router Bit?

Compression spiral router bits are a combination of the above two, with an up and a down spiral, so it's called "compression". The former is on the tip of the bit, and the latter is close to the shank.

These bits, combining the advantages of the first two, make the chips eject from the up and down sides to ensure a smooth surface both on the top and the bottom, and produce a perfect trimming effect.

Also read: Spiral Router Bit vs Straight Router Bit: Which One is Better

Key Differences Between Upcut, Downcut, and Compression

Upcut, downcut, and compression bits are the common spiral router bits, but they differ greatly from one another in some aspects.

1. Cutting Action:

The main difference between an upcut, a downcut, and a compression bit is the direction of cutting and rotation.

When you observe them from left to right, if the flute rises to the right, it's an upcut; on the contrary, if the flute descends to the right, it's a downcut. And for the compression bit, the first quarter of it is upcut, and the rest of it is downcut.

2. Chip Removal:

We mentioned above that the direction of cutting decides the direction of chip removal. The upcut bit can eject chips efficiently and allow a faster feed rate, while the downcut needs a slower feed rate due to the chip buildup.

Compared to them, the compression bit allows a smoother and faster cutting and achieves a better chip ejection to gain a cleaner surface.

3. Cutting Material:

Both the upcut and downcut spiral router bits are suitable for carving and engraving. But the upcut bits are far more universal than the downcut. They won't tear out the materials, and are widely used for making dados, mortises, tenons, and shallow grooves in bottom-veneered boards.

And the downcut bits are widely used for creating clean edges on inlay, plywood, or laminated.

Made from carbide, the compression spiral router bits are sharp and durable. So it's ideal for cutting double-sided veneers, softwood, hardwood, MDF, laminates, and composite materials.

Considerations & Suggestions

It's important to choose a compatible router bit for every woodworking project. When choosing these three types of spiral router bits, you need to consider the effect you want.

For instance, if you want to make mortises, an upcut bit is more suitable, for it can remove the chip from the hole effectively. While if you want to work on inply, a downcut bit is better. And for compression bit, it's a superior choice in most applications.

Choosing the right spiral router bit can make your woodworking projects twice as easy. And if you are still confused about them or have any questions while choosing, you can email us for professional suggestions.

Findbuytool offers a diverse range of high-quality upcut, downcut, and compression spiral router bits, providing you with the perfect tools you need to achieve exceptional results.

We combine micro-grain carbide, a full CNC production line, a top-quality steel body, and self-invented product quality inspection procedures to produce industrial-grade CNC router bits for our customers. We hope this guide will improve the outcome of your future projects.

If you still have any questions about these three types of spiral router bits, you can leave a comment, and we will reply to you via email ASAP.

FAQ about Upcut VS. Downcut VS. Compression

#1 What is the difference between up cut and downcut?

The primary difference lies in the direction of cutting and rotation. From left to right, the flute rises to the right, it's upcut; the flute descends to the right, it's downcut.

#2 Is upcut or downcut better for dado?

Upcut is better. The upcut router bit won't tear out the material and allows a faster feed rate, thus, it's more suitable for dado than the downcut.

1 comment

I wish to cut cut circles from mid grade plywood for clock making. I’m thinking a compression bit would be best. Is that true?